Warping

Fully electronic Warping Machine from TechMech, Ahmedabad, India. It has the capacity of preparing a warp up to 5-6 thousand meters in minimum 3-4 hours

Rapier Machines

We have 14 fully electronic Weaving Rapier Machines from Vamatex, Italy. A team of two skilled masters and 6 helpers take care of this unit. We have an average production rate of 1500 meters of fabric per day. Although the production rate differs sometimes due to complexity of the design.

Jacquard

Looms to produce fabrics having intricate woven patterns such as tapestry, and damask, and it has also been adapted to the production of patterned knitted fabric:

Products that we manufacture

- Cushions

- Pillows

- Rugs

- Throws

- Wall arts

- Heavy fabric

- Runner

- Wall hanging

Jiggers

Discover our cutting-edge12 jigger machines, revolutionizing textile production. Engineered with precision and efficiency in mind, our state-of-the-art jigger machines offer seamless fabric dyeing and processing.

Equipped with advanced mechanics and intuitive controls, they ensure optimal tension control and flawless results. Experience enhanced productivity and superior quality with our reliable jigger machines, designed to elevate your textile manufacturing capabilities. Explore our range today and transform your production line.

Hanks dyeing Chamber Machine

Introducing our innovative hanks dyeing Chamber machine, a game-changer in textile dyeing. With its advanced technology and precise temperature control, our machine ensures impeccable color penetration and uniform dye distribution. Designed for efficiency and versatility, it accommodates a range of hank sizes and dyeing requirements. Experience faster turnaround times and vibrant, long-lasting colors with our cutting-edge Hanks dyeing Chamber machine. Elevate your dyeing process and exceed customer expectations. Explore our offerings today.

Hydro Extractor

Discover the power and efficiency of our Hydro Extractor machine, an essential component of textile processing. With its robust construction and high-speed rotation, our machine effectively removes excess water from fabrics, reducing drying time and energy consumption. Equipped with advanced safety features and user-friendly controls, it ensures reliable and consistent performance. Boost your productivity and optimize your operations with our reliable and durable Hydro Extractor machine. Explore our range today for enhanced efficiency.

Tumble Dryers

Experience exceptional drying performance with our cutting-edge 2 tumble dryers machines. Designed for efficiency and convenience, our machines offer rapid and uniform drying of textiles, ensuring quick turnaround times. Equipped with advanced sensors and customizable drying programs, they provide precise temperature and moisture control. With their durable construction and user-friendly interface, our Tumble Dryers machines are the ideal choice for optimizing your drying processes. Explore our range today for superior drying results.

Hot Air Stenter

Introducing our state-of-the-art Hot Air Stenter machine, a game-changer in textile finishing. Engineered for precision and performance, our machine ensures consistent and uniform drying, heat setting, and fabric stretching. With advanced temperature and airflow control, it delivers impeccable results and enhances fabric stability. Equipped with user-friendly features and customizable settings, our Hot Air Stenter machine empowers you to achieve superior finishing quality. Explore our range today and elevate your textile production capabilities.

Screen Printing

Printing unit has 20 screen printing operators with a capacity of 2000 sq mt. Per day. We offer a wide range of customizable soft home textile products including pillows, throws, rugs, and cotton fabrics. Our master’s craftsman skillfully prints each motif to impress color on the fabric, which exhibits the character of the royalty. Without compromising on design and quality, we provide high definition screen printing according to buyer recommendations and current market trends.

Laboratory Unit

The spectrophotometer works by passing a light beam through a sample to measure the light intensity of a sample.

Laboratory dyeing machine uses InfraRed heating elements. No disturbing fumes, gasses and noise in the laboratory. Seamless stainless steel beakers are used for dyeing samples.

Machines in the laboratory

- Spectrophotometer –

- Colour Matching Cabinet by X-Rite

- Colour IR Dyeing Machine

- Tensile Strength

- Pilling Tester

- Colour Fastness to Washing

- Colour Fastness to Rubbing

Frame Loom

A loom is a tool employed for the creation of cloth and tapestry by intertwining warp threads with weft threads. While the specific design and mechanics of looms may differ, their fundamental purpose remains consistent: to maintain tension on the warp threads, enabling the interlacing of the weft threads.

Jute Braided Production Unit

Our domain expertise has enabled us to come up with an excellent collection of Jute Braid for our esteemed clients. Our offered Jute Braid are available in diverse technical specifications and find extensive usage in handcuffs. The provided Jute Braid are manufactured using the optimum grade raw material and modern techniques under the surveillance of our vendors’ professionals. Key features:

- Withstand high temperature

- Light weight

- Corrosion resistance

Products that we manufacture :

- Rugs

- Baskets

- Placements

Tufting Production Unit

This unit has 10 semi-automatic electronic tufting machines from Siraj New -Tech, Panipat, India.

Tufting is an art of creating three-dimensional textile surfaces with the help of needles. We are trying to take this craft to a level where creative minds and our craftsman’s skill meet on the same horizon creating a stunning range of exquisite products.

Stitching Unit

The stitching unit is set up in-house with 60 stitching machines from Brother & Juki, Japan. Our trained, skilled and experienced tailors are responsible for transforming our beautiful fabrics into our high end products.

Polyester Filling Unit

We are into offering Polyester Fiberfill. We offer this Polyester Fiberfill, which makes your pillows, stuffed toys and other such items softer and fluffier. Products stuffed with polyester fiberfill can also be Vacuum Packed for saving Logistics cost.

Capacity 75000 units per month

Cotton Filling Unit

We have an in-house filling unit which upcycles the post-consumer cotton wastes. Each piece is hand-filled and hand tucked with Love.

Finishing Unit

To maintain the quality and finish each piece goes through the finishing department before being packed.

There is a team of workers depending upon the work-load to complete this process of clipping, repairing and finalizing.

After this check, defected pieces are discarded from the lot and others are sent for packing.

Office Contacts

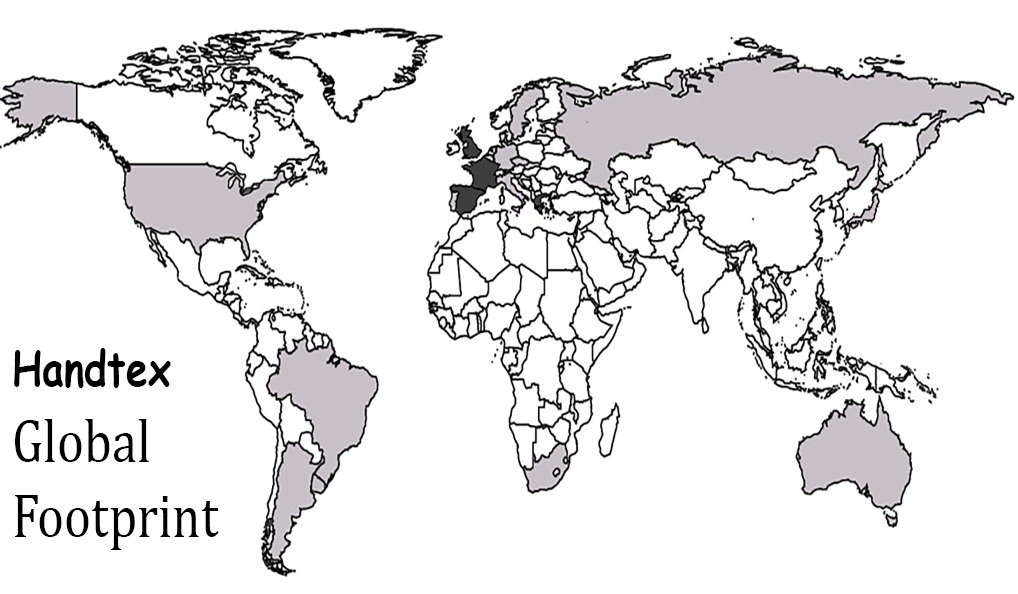

Join Handtex and embark on our founder Gian Miglani’s inspiring journey, from establishing four handlooms to a 5 million USD company. We value our team, suppliers, and customers, foresting a close-knit family environment. Deligh your customers with our 5000 home furnishing products. Let’s connect.

Panipat 132103, Haryana India